Advanced Scientific and Engineering Services (AdvanSES) offers a wide range of mechanical and materials testing to evaluate metals, polymers, composites and engineering products.

Testing is always carried out in compliance with IS, ASTM, ASME, DIN, API, JIS specifications. Non-standard Testing can also be done to evaluate materials as per Z-call outs and customer specifications.

Testing at AdvanSES material testing laboratory is a high precision process that measure mechanical and material properties for integrity and reliability. We report on the test data and results whether the products and materials meet the requirements of design engineers and regulatory agencies. We also assist on failure analysis and failure modes and effect analysis of engineering materials and components.

SERVICES PERFORMED IN OUR MATERIAL TESTING LABORATORY

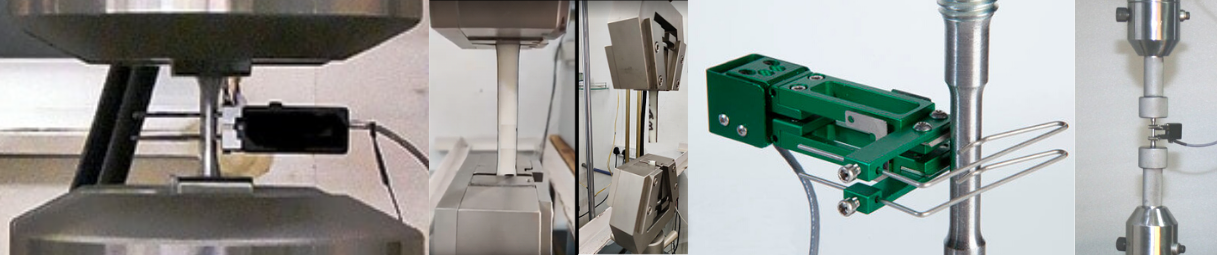

MECHANICAL TESTING

Mechanical testing measures the strength and characteristics of materials under various conditions, such as temperature, tension, compression and load. AdvanSES performs the testing and provide the data for proof load, stress rupture, charpy impact, yield, bend, hardness, and much more.

FRACTURE MECHANICS

Fatigue Crack Growth Testing and Fracture Toughness Testing as per ASTM standards are carried out. Specimen machining is carried out at our in-house machine shop.

DYNAMIC MATERIAL TESTING

Dynamic material testing includes testing for loss modulus, storage modulus and tan delta properties for different non-metallic materials. Our characterization lab will provide all the test data for you to completely characterize the dynamic properties of polymers and rubber materials.

VISCOELASTIC MATERIAL TESTING

All engineering materials suffer from creep and stress relaxation throughout their application and service life. AdvanSES has full capability to characterize these difficult to characterize viscoelastic material properties. Our viscoelastic characterization lab will also provide all the test data for you to model and analyze these properties in FEA, CAE application softwares.

FATIGUE TESTING

Fatigue testing on materials and components is carried out to evaluate their durability under service loads. Our capabilities include testing the materials and components under wide range of loads, frequencies and environment conditions.